What We Work With

Maintainer/Motor Grader

A grader, also commonly referred to as a road grader, motor grader, or simply blade, is a form of self-propelled heavy equipment with a long blade used to create a flat surface during grading. Typical graders have three axles, with the steering wheels in front, followed by the grading blade or mouldboard, then a cab and engine atop tandem rear axles. Some graders also have front-wheel drives for improved performance. Some graders have optional rear attachments, such as a ripper, scarifier, or compactor. A blade forward of the front axle may also be added.

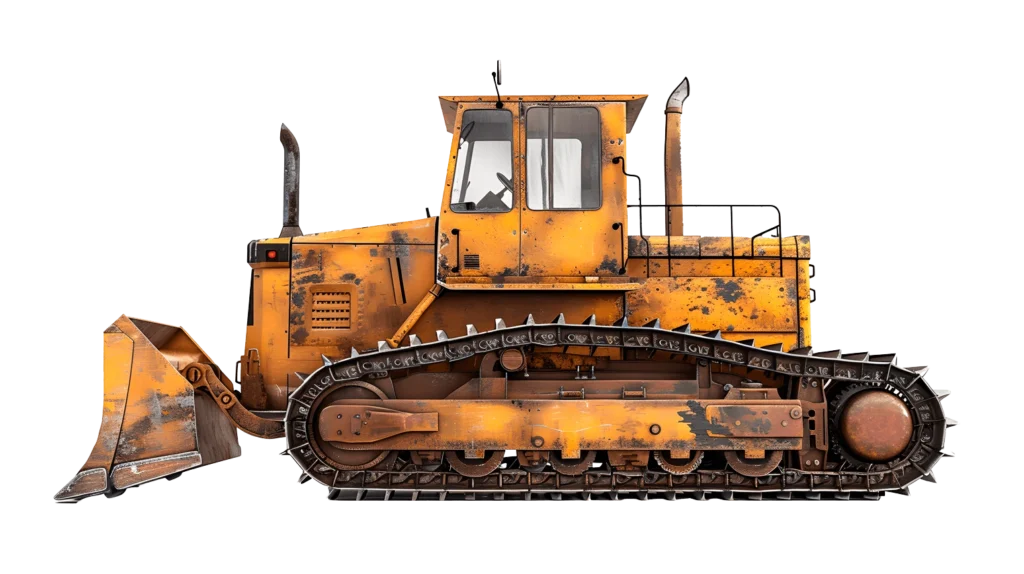

Bulldozer

A bulldozer or dozer is a large, motorized machine equipped with a metal blade to the front for pushing material: soil, sand, rubble, or rock during construction work. It travels most commonly on continuous tracks. Its most popular accessory is a ripper, a large hook-like device mounted singly or in multiples in the rear to loosen dense materials. Bulldozers are used heavily in large and small scale construction & road building.

Skid Steer/Front End Loader

A skid loader, skid-steer loader, SSL, or skidsteer is any of a class of compact heavy equipment with lift arms that can attach to a wide variety of buckets and other labor-saving tools or attachments. The wheels typically have no separate steering mechanism and hold a fixed straight alignment on the body of the machine. Turning is accomplished by differential steering , Skid-steer loaders are capable of zero-radius turning. This “zero-turn” capability (the machine can turn around within its own length) makes them extremely maneuverable and valuable for applications that require a compact, powerful and agile loader or tool carrier in confined-space work areas.Like other front loaders, they can push material from one location to another, carry material in the bucket, load material into a truck or trailer and perform a variety of digging and grading operations.

Steel Wheel/Vibratory Roller

A vibratory roller, also known as a vibro-roller or a compactor, is a heavy-duty construction machine designed for soil compaction and asphalt paving. It is commonly used in road construction, building foundations, and various infrastructure projects to ensure the structural integrity of the surface. Vibratory rollers are called so because they use vibrations to compact materials efficiently

Asphalt Paver/ Laydown Machine

A paver (road paver finisher, asphalt finisher, road paving machine) is a piece of construction equipment used to lay asphalt aggregates on driveways ranch roads, parking lots, air strips and other such places. It lays the material flat and provides minor compaction. This is typically followed by final compaction by a road roller.

Pneumatic/ Rubber Tire Roller

Pneumatic tyred rollers, also known as rubber-tired rollers or pneumatic rollers, are heavy construction machines used for road compaction. They are equipped with multiple rubber tyres on both the front and rear axles, which can be adjusted to control the level of compaction. The flexibility of the rubber tires and their ability to adjust air pressure allows these rollers to effectively compact various materials like soil, asphalt, or aggregates. These rollers are commonly used to achieve smooth and even surfaces on roads by applying pressure evenly across the surface during compaction.

Tack Truck/Oil Distributor

An asphalt distributor’s main job is to apply tack or bond coat to a road surface. When sprayed onto pavement, the treatment functions as a “glue” to hold existing and new pavement layers together. This enhances the bonding of individual pavement layers so they function as a single, unified pavement for improved strength and durability.

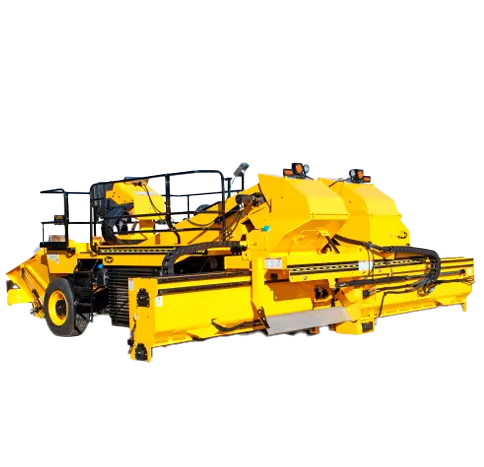

Chip Spreader

A chipping spreader is a machine that lays coated chippings on roads for a maintenance treatment called a chip seal. There are many different types of chipping spreaders. Although they are all managed differently each is designed to spread chips in road construction.